Vertical Impact Crusher

This machine is is used as tertiary stage of crushing. The current criteria for manufacturing sand for use in concrete and asphalt are compatible with the vertical impact crusher machine’s ability to generate multifaceted mixed soil.

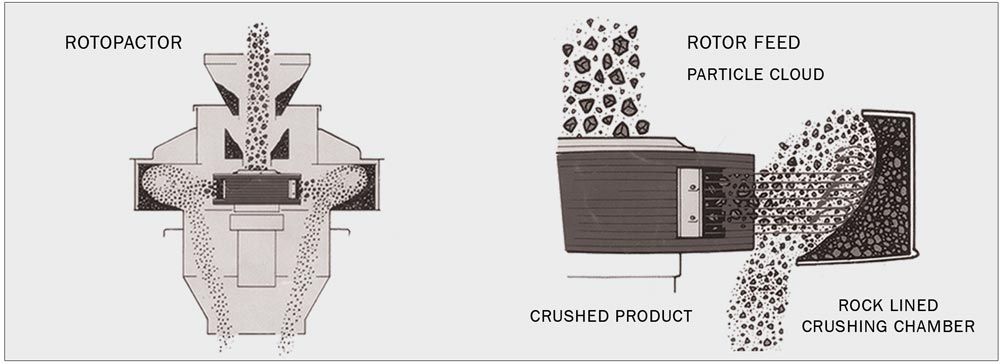

Hard stones like feldspar, silica, dolomite, and barite are typically ground in vertical impact crushers or “rock on rocks,” and the grinding process in these machines acts as a self-breaker. It should be mentioned that the rotor, which is the most important component of the Rock on Rock machine, is constructed of Hardox 400 and that all of the hammers are made of tungsten carbide.

Advantages:

- minimal depreciation

- a high rate of grinding

- Simple to maintain