Metal Cutting Guillotine also known as a Shearing Machine is supposed to cut Metal Sheets of different thickness. Cutting of the sheet is proceeded with the help of Shearing blades, Upper movable and Lower stationary. Thickness of the sheet is veryfied and quality of cutting depends of Machine capacity and type of Material.

Press Brake Bending Machine is a perfect way for bending and shaping of Metal sheets. Bending Tools such as Punch and Matrix are helping with that. The shape of punch and matrix depends on the way you want to form the sheet. Both full-length and segmental tools can be supplied by TFI. Power of the machine plays a decisive role in bending and should be chosen depending on the sheet thickness and necessary bending shape.

Ironworker is a class of machines that can shear, notch, and punch holes in Metal sheet. High strength carbon Steel Blades and Dies of various shapes are used to work the metal. The machine itself is made of very heavy steel to handle the enormous force that can be generated during use. Operations which can be performed include: Shearing, Punching, Notching, Forming or bending. Due to the reduction in the amount of man hours and effort needed to cut or punch steel sections, an ironworker is often an integral part of commercial manufacturing facilities and fabrication shops.

Bandsaw Machine is a saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches (teeth per inch, or TPI), which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

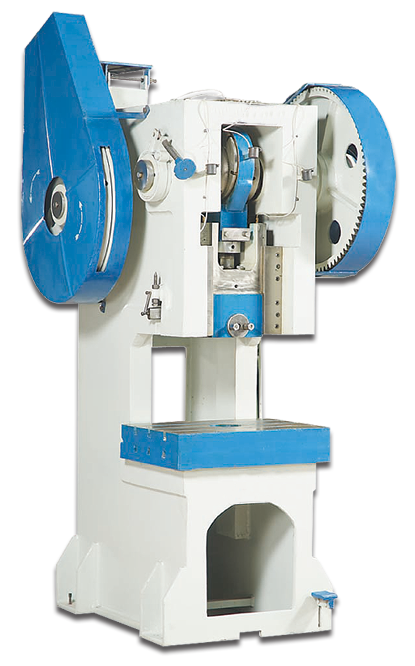

A forming press, commonly shortened to press, is a machine tool that changes the shape of a workpiece by the application of pressure. Typically consisting of a simple rectangular frame, often fabricated from C-channel or tubing, containing a bottle jack or hydraulic cylinder to apply pressure via a ram to a work piece. Often used for general-purpose forming work in the auto mechanic shop, machine shop, garage or basement shops, etc.

A Roll bender is a mechanical jig having three rollers used to form a metal bar into a circular arc. The rollers freely rotate about three parallel axes, which are arranged with uniform horizontal spacing. Two outer rollers, usually immobile, cradle the bottom of the material while the inner roller, whose position is adjustable, presses on the topside of the material. The material to be shaped is suspended between the rollers. The end rollers support the bottomside of the bar and have a matching contour (inverse shape) to it in order to maintain the cross-sectional shape.

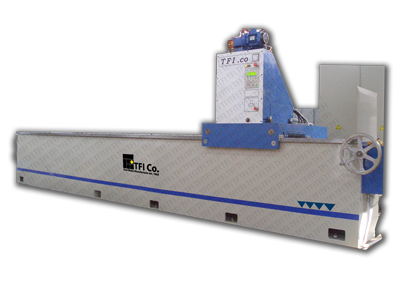

Surface grinding is used to produce a smooth finish on flat surfaces. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth. The machine consists of a table that traverses both longitudinally and across the face of the wheel. The longitudinal feed is usually powered by hydraulics, as may the cross feed, however any mixture of hand, electrical or hydraulic may be used depending on the ultimate usage of the machine (i.e., production, workshop, cost). The grinding wheel rotates in the spindle head and is also adjustable for height, by any of the methods described previously.

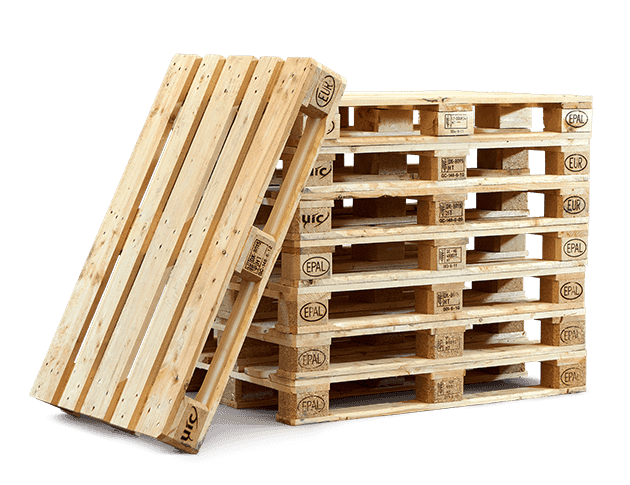

The wood pallet making machine also called wood pallet machine, wood pallet moulding machine, is a new type of one time forming machine. The compressed wood pallet has been widely used in the storage and transportation of many industries such as food, tobacco, pharmaceuticals, chemical, machinery, electronic appliances, auto parts, beer and others, which greatly improve the work efficiency.

Folding machines also bend metal, the difference between it and a press brake is how that bend is achieved. Folding machines use much less force, leading it to be used for much thinner sheets. Where the force of a press brake could potentially scratch and damage a very thin sheet, a folding machine is much more delicate and produce items where look and style are paramount. Folding machines will be much better and quicker with panel work of all sizes. They are also better for jobs require multiple tooling changes.

When a tube is bent, the outside wall of the tube collapses or thins out, and the inside of the tube compresses and wrinkles.

Our Sistan machine are reliable for hallow section bending in the market

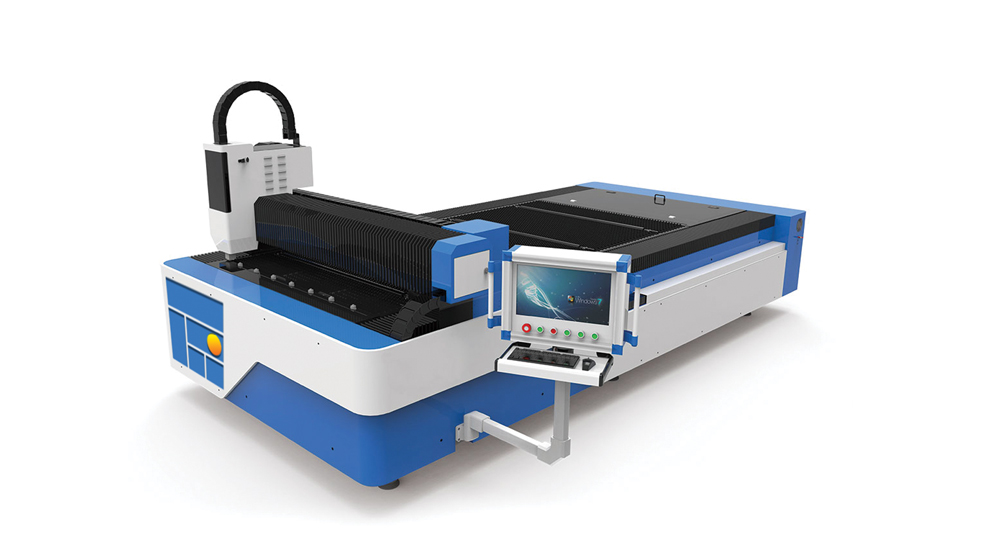

Cutting and Perfect trimmings with only TFICo Fiber Laser Cutting Machines for sheets up to 20 mm thickness. Fiber Laser machines can be used for marking, auto industry, cleaning, engraving and drilling! TFICO at your service.